AUTOMATIC CAN SEAMING MACHINE:-

MODEL NO. AM 220 :-

These machines can be used for seaming round can such as metal, plastic and composite containers.

SILENT FEATURE :-

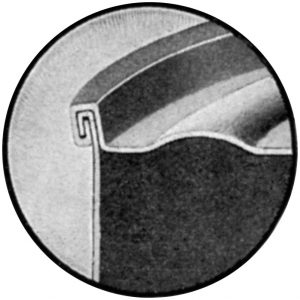

- FOUR seaming ROLLER FOR LEAK PROOF SEAMING

- Automatic lid feed system

- Easy to changeover

- All moving parts are covered for safety

- Rugged design

- High production

- Noiseless

- Easy to maintain

- Contact elements and tooling comprised of stainless-steel / brass (non-compulsory)

- Seaming subject is included with a transparent acrylic quilt for unobstructed view of the working field and total operator safety

- Easy to operate

- 22 min. For seaming roller and height changed

- On hand in quite a lot of configurations to swimsuit client requirements

DESCRIPTION OF OPERATION :-

Cans are fed from present conveyor or a rotary desk onto the laptop conveyor. They’re mechanically listed into the seaming system. The ends are positioned on to the Can; it is seamed and exited on the output side of the machine.

The desktop will also be outfitted with a couple of choices such as nitrogen spraying, product filling nozzle, weight checking method, and so on.

TECHNICAL SPECIFICATIONS :-

| Output Capacity | 28 / 32 Cans Per Minute |

| Diameter Range | 38 to 200 mm |

| Max. Container Height | 250mm |

| Max. Sheet Thickness | 0.15 to 0.50mm |

| Motor Power | 3 HP / 1440 RPM |

| Net Weight | 800 Kgs (approx.) |