SEMI AUTOMATIC CAN SEAMING MACHINES

MODEL NO. CM 220 /CS 220

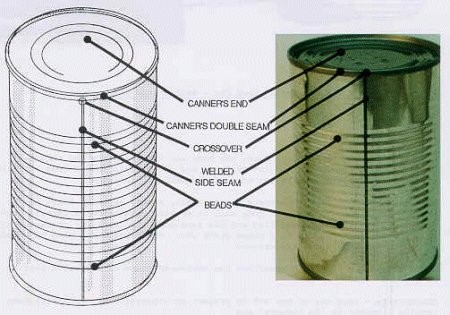

These machines are used for seaming round can such as metal plastic composite containers. The rotating head design maintains a stationary can during the seaming operation our machine are not produce type of pollution such as noise our design are rugged. A wide range of safety features and interlocks are available to protect both operator and equipment

SILENT FEATURE

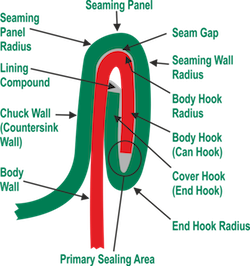

- Four ROLLER Seaming ensures constant and leak proof Seaming

- High speed for high production

- Low maintenance and high efficiency

- Ability to seam a broad variety of Can Diameters with a fast changeover of tooling. For peak changes most effective a simple surroundings is required (no change constituents).

- Push Button or Foot change operation with Pneumatic Lifting method

DESCRIPTION OF OPERATION

The Can with the Lid (finish) to be Seamed is placed on the lifter plate and the pedal are pressed. The Can is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Can are mechanically brought down to the rest position

WITH FOOT SWITCH

The Can with the Lid (end) to be seamed is positioned on the lifter plate. A Foot switch (electronic) is pressed and the seaming operation begins. After completion, the lifter plate with the seamed Can is robotically brought right down to the leisure position.

The Can with the Lid (finish) to be seamed is placed on the lifter plate. The dual push buttons are concurrently pressed and released. The Can is lifted to the Seaming Chuck and the seaming operation begins. After completion, the lifter plate with the seamed Can is robotically introduced all the way down to the leisure function.

TECHNICAL SPECIFICATIONS

| Output Capacity | 26 / 32 Cans Per Minute |

| Diameter Range | 40 to 200 mm |

| Max. Container Height | 250 mm |

| Max. Sheet Thickness | 0.15 to 0.50mm |

| Motor Power | 1 HP / 960 RPM |