AUTOMATIC FILTER SEAMING MACHINE:-

MODEL NO. AM 250:-

These machines can be used for spin-on oil filter seaming. RAMGARHIA PACKAGING INDUSTIES offers a line of heavy duty seamers capable of handling even the heavier gauge SHEET used in high pressure oil filters.

SILENT FEATURE:-

- Four roller for leak proof seaming

- Compatible for Can Filters

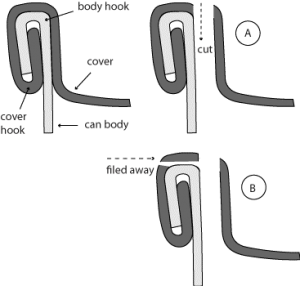

- Four roller double seaming design for regular leak-proof seaming

- Filters with ends are consumed the laptop on pucks (filter holders) constructed from nylon

- Easy to changeover

- Rugged design

- High production

- Noiseless

- Easy to maintain

- Easy to operate

- Rapid dimension changeover time, 21 minutes for diameter changes and 6 minutes for height changes

- All safeguard covers are equipped with defense interlocks

- On hand with not obligatory full laptop enclosure and Loop Conveyors for continuous movement of Pucks (Filter Holders)

DESCRIPTION OF OPERTION:-

Filters fed from present conveyor or a rotary desk onto the laptop conveyor. They’re mechanically listed into the Seaming system.

The Ends are positioned on to the filter, it is Seamed and exited on the output side of the MACHINE.

TECHNICAL SPECIFICATIONS:-

| Output Capacity | 22 Cans Per Minute |

| Diameter Range | 40 to 150 mm |

| Max. Container Height | 250mm |

| Max. Sheet Thickness | 0.80 mm |

| Motor Power | 5 HP / 1440 RPM |

| Net Weight | 800 Kg (approx.) |